Commissioned Chemical Processing

Commissioned processing

We provide total support, including various processes to meet customer needs using a diverse range of ion-exchange resin and separation membrane related processing equipment, for which we have many years of experience and proven results, recycling processes to help customers reduce their costs, and all types of analyses and tests to ensure safety and reliability.

Commissioned processing

We use our technologies and experience developed over many years in the ion-exchange resin and separation membrane fields to perform each step from ion-exchange resin processing to separation membrane cleaning and product management. We use separate dedicated facilities for ion-exchange resin and separation membranes. We can accommodate all types of applications from pharmaceuticals and food products to pure water and ultrapure water.

Ion-exchange resin ion substitution and regeneration systems

Performs everything from regeneration of ion-exchange resin for pure water to substitution to the desired iron shape, pure water cleaning, and ultrapure water cleaning.

Can also perform thermal regeneration and hot pure water cleaning.

For specialty applications, the catalyst support and resin particle size can be adjusted through classification, or deodorization treatment can be performed on the resin, for example.

Ion-exchange resin ultrapure water cleaning systems

A polisher tank for ultrapure water sampling is filled with ion-exchange resin that is then cleaned with ultrapure water.

After cleaning, nitrogen purging is performed on the polisher tank before delivering the product.

Ion-exchange resin dryers

Fluidized dryer that dries ion-exchange resin. It is installed in clean rooms to prevent contamination by impurities.

This dryer is specially designed for ion-exchange resin, and can efficiently dry ion-exchange resin without reducing its performance.

Ion-exchange resin mills/classifier

Ion-exchange resin is pulverized and the resin grains are sorted by size. As this process is particularly susceptible to problems with impurities, special purpose mills are installed in clean rooms.

UF/MF membrane cleaners

Cleaning of UF membranes and RO membranes with ultrapure water can reduce start-up time at facilities. Used UF and RO membranes can be chemically rinsed and reused.

RO/UF membrane cleaners

Cleaning of RO membranes and UF membranes with ultrapure water can reduce start-up time at facilities. Used RO and UF membranes can be chemically rinsed and reused.

Analysis and testing

Analysis and testing

We support customers on various fronts, including assistance developing new projects, analysis of raw liquid, and health diagnosis of the ion-exchange resin being used.

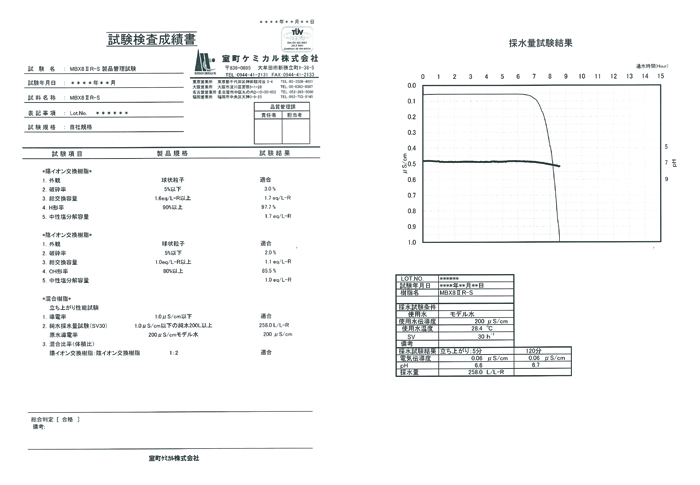

Product testing

Dedicated staff responsibly confirm the quality of products being treated or processed.

We continuously investigate new analytical methods and devices to accommodate the product standards of the customer.

Analysis and testing equipment

- ICP-AES emission spectrophotometer

- Atomic absorption

- Ion chromatograph

- Total organic carbon analyzer

- Gas chromatograph

- High-performance liquid chromatograph (HPLC)

- FT-IR infrared spectrometer

- Laser diffraction particle size distribution analyzer

- Karl Fischer moisture meter

- Infrared moisture meter

- Precision refractometer

- UF membrane test device

- RO/NF membrane test device

- Cross-flow test device

Recycling

Ion-exchange resin

We perform regeneration treatment on used ion-exchange resin and synthetic adhesives at our own plant. Before shipping products, we check not only the regeneration rate after regeneration, but also the resin performance before regeneration and flow after regeneration.

For the raw water used in sampling tests of ion-exchange resin for pure water applications, we use “model water” with a constant conductivity, ensuring constant delivery of highly reliable regenerated resin that exceeds given standards.

Separation membranes

Regeneration and cleaning of RO, UF, and MF membranes that have been used or are currently in use are performed at our own plant. Our membranes are highly evaluated by users at water filtration plants, semiconductor plants, food product plants, and other plants. In addition to checking the transmission volume and treated water quality after regeneration, we also check the flow performance before regeneration and test the cleaning method before starting the recycling process.